Depend on Diedrich for

Innovative Coffee Processing & Roasting Technology

Manufactured & Supported in the USA.

Experience the Diedrich Difference

Our goal is your success! We use our extensive industry knowledge and experience to identify your specific needs, analyze your workspace, workflows, and create appropriate capacity goals. Our expert team partners with you to design the precise roasting system and business strategies for success.

Noteworthy Consulting

Grow Your Business with Expert Advice and Support

Equipped to help grow your business

with expert advice and exceptional support.

In addition to crafting exceptional specialty and commercial roasters, Diedrich offers world-class consulting, facilities concept design, and comprehensive educational programs in all facets of the coffee industry. With decades of experience, we are able to explore and facilitate all segments of the market by incorporating innovation and new technologies to meet today’s challenging demands.

We Partner with You to Identify Your Specific Needs, Analyze Your Workspace & Workflows, and Create Appropriate Capacity Goals

With locations in Chicago and Idaho, our US-based team is easily accessible to our customers. Our core competencies and deliverables are based on designing precise roasting systems, business strategies, and complete support for your success and profitable growth.

Our Facilities & Concept Design Services Include

BUSINESS PLANNING & MANUFACTURING STEPS

- Business plan development

- Facility evaluation

- Definition of current and future state

manufacturing analysis and strategy - Production and inventory control techniques

- Identifying and understanding your market

- Distribution Strategy

- Sales and Marketing Plans

- Quality Control System Development

- Employee Safety & OSHA concerns

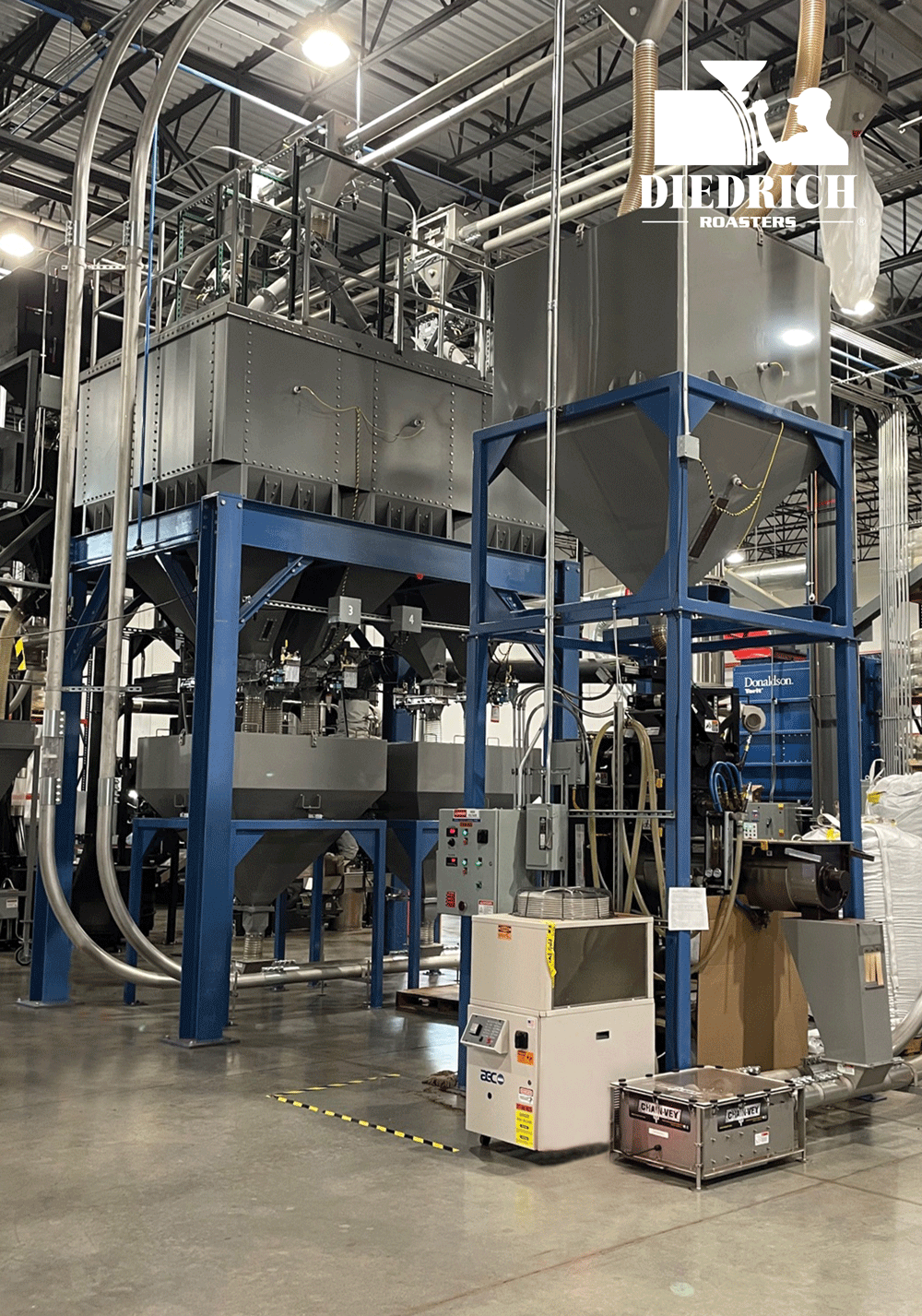

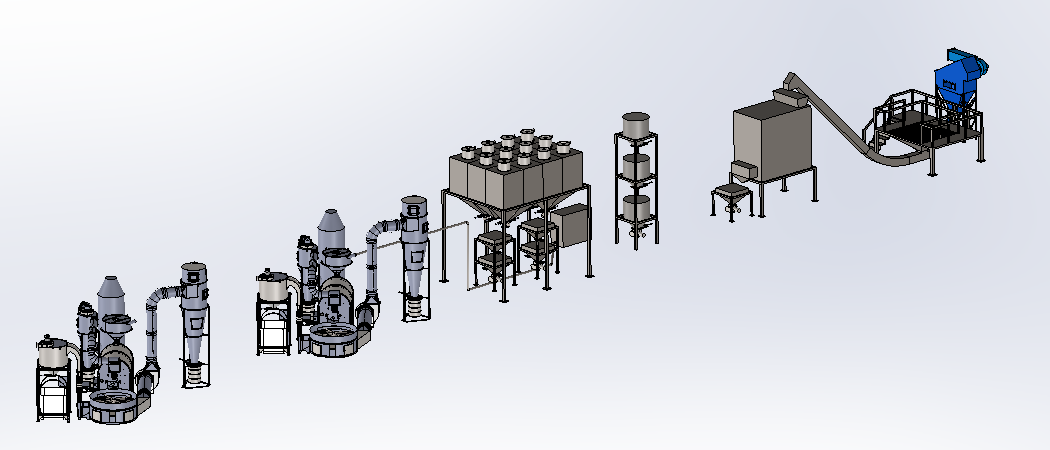

PROCESS ENGINEERING SERVICES

- Process project development

- Process packaging design and engineering

- Equipment specifications and procurement

- Line layouts, process or packaging

- Electric/controls

- Equipment installation

- Startup and commissioning

SERVICES

- Equipment field support

- Café design and training

- Roaster Training

- Food Safety

- Regulatory Agency Changes

- Permitting Services

- Risk Management thru the whole chain

- Equipment decisions

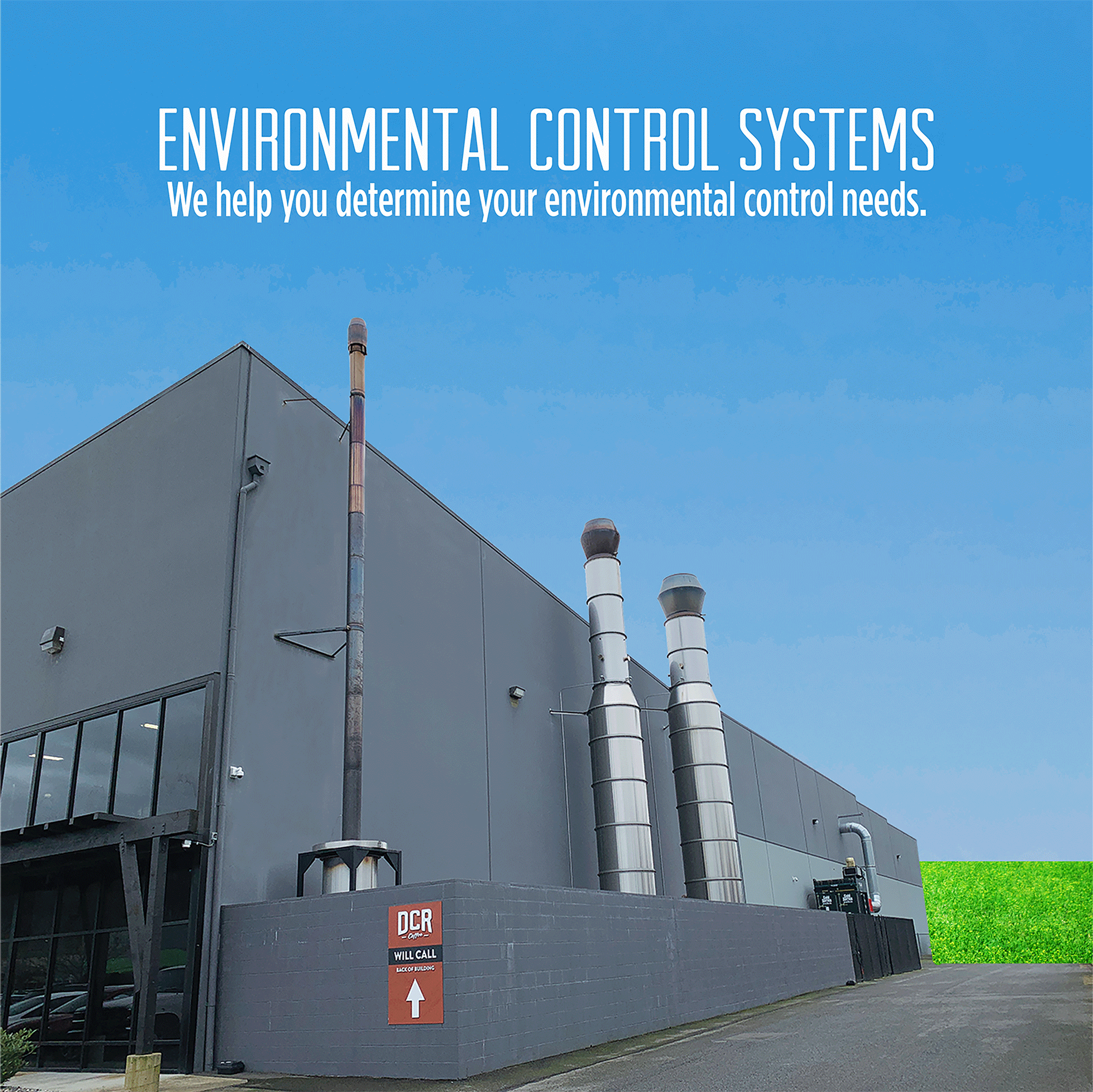

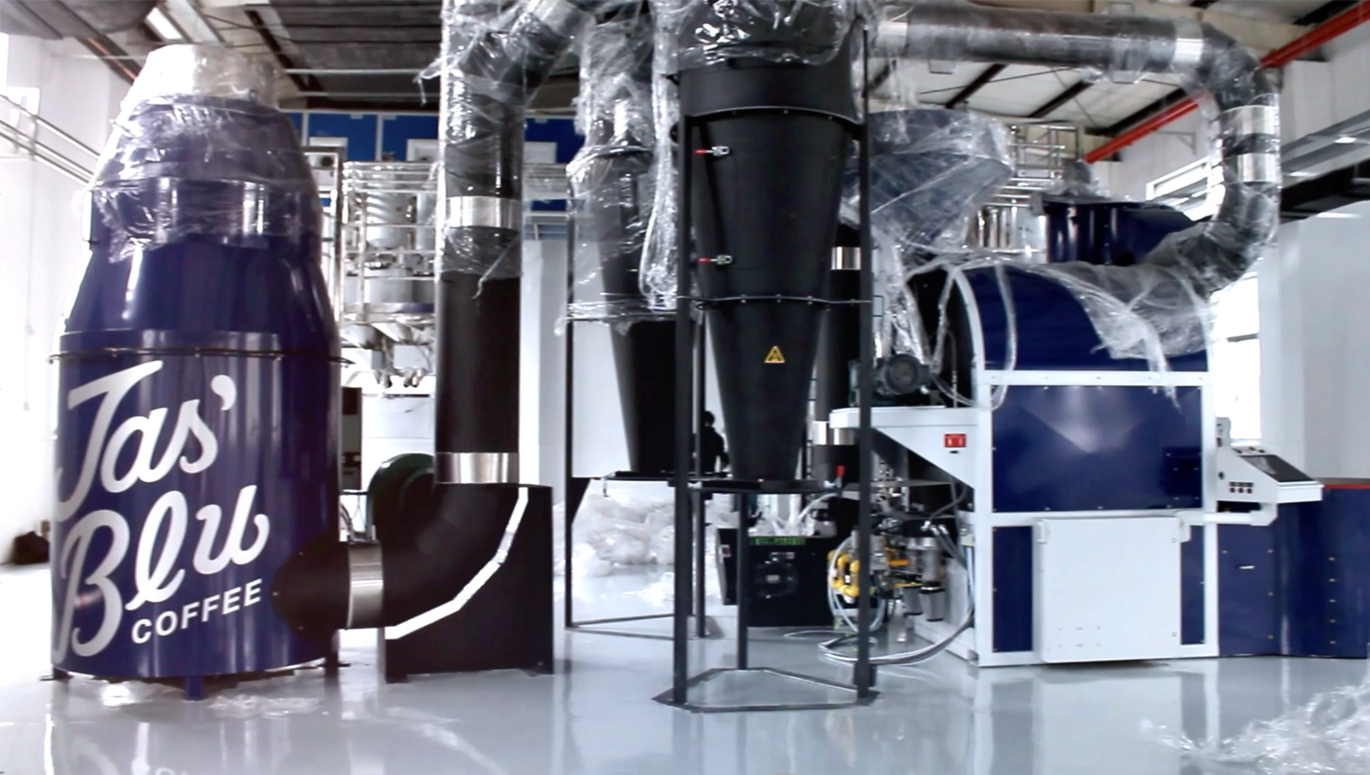

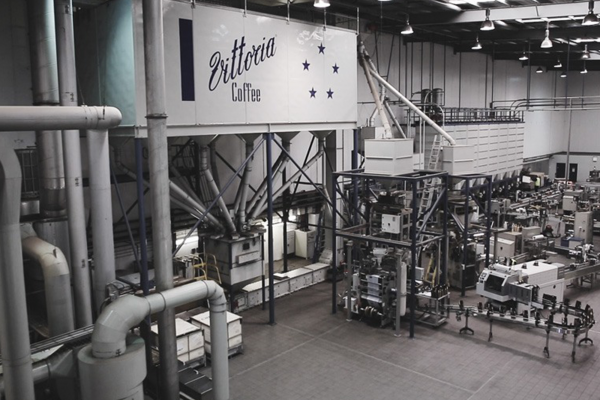

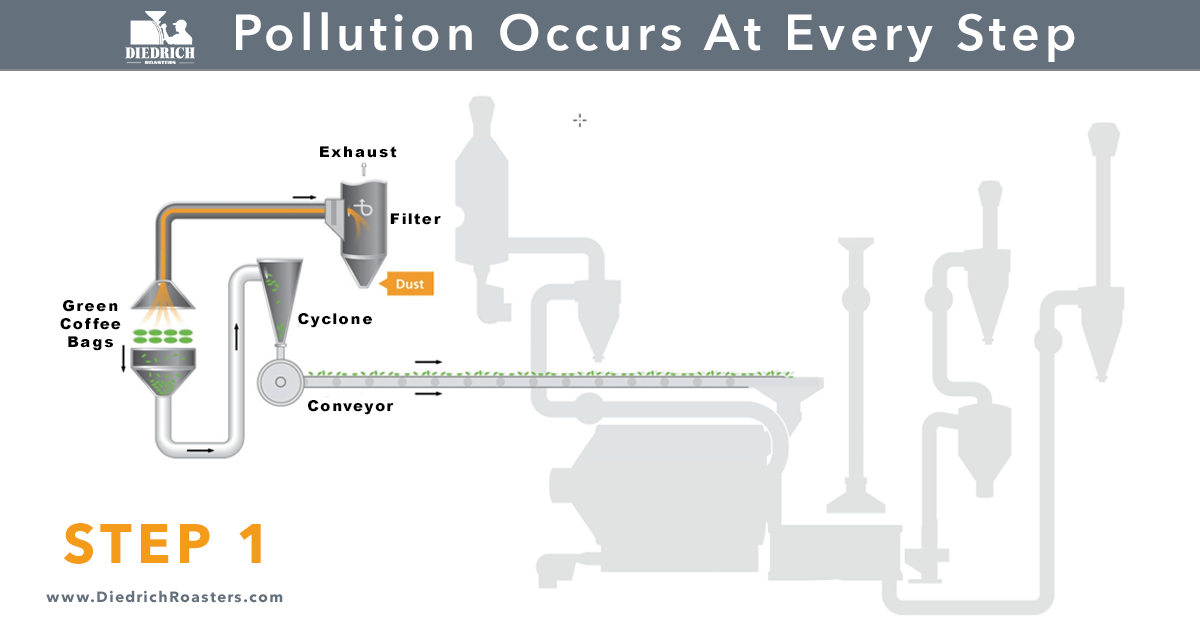

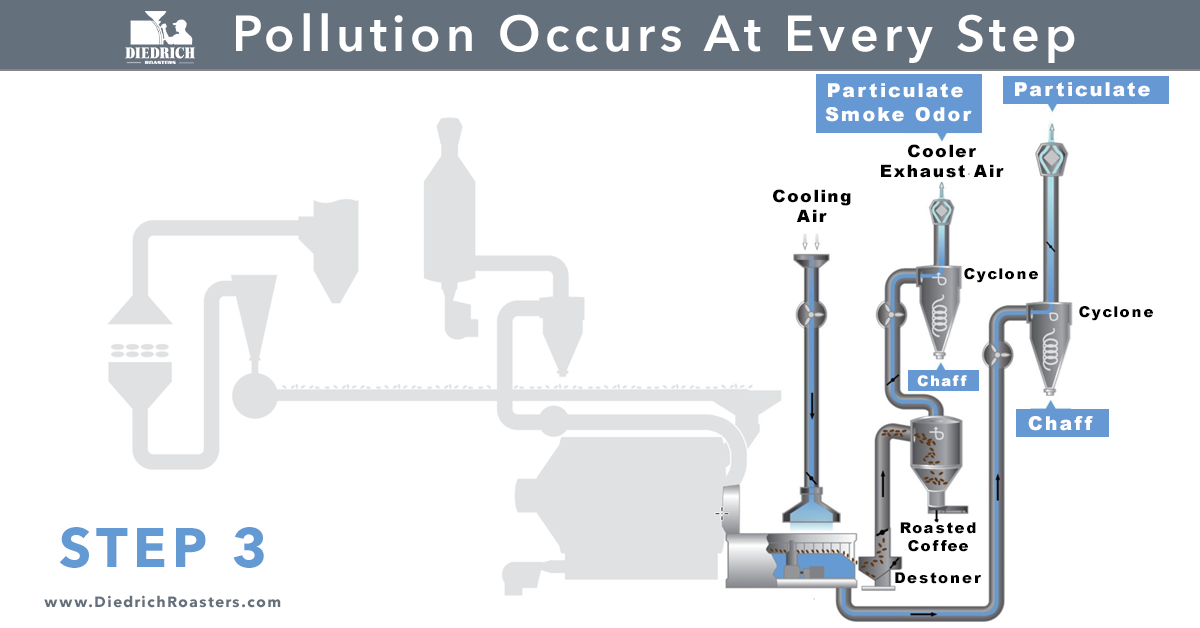

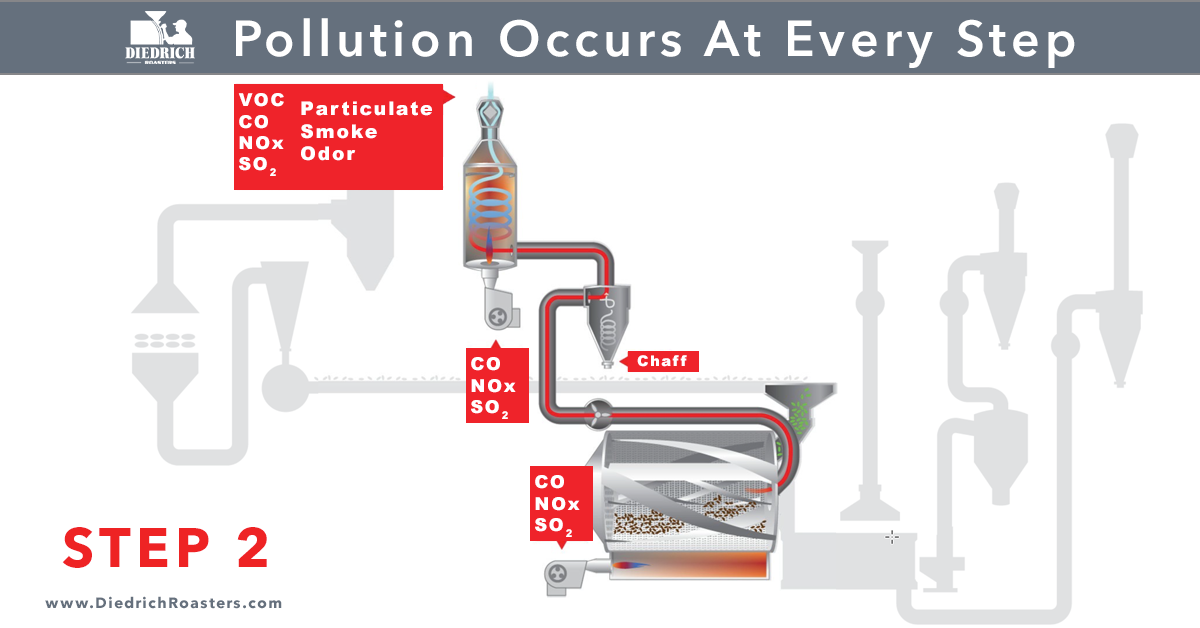

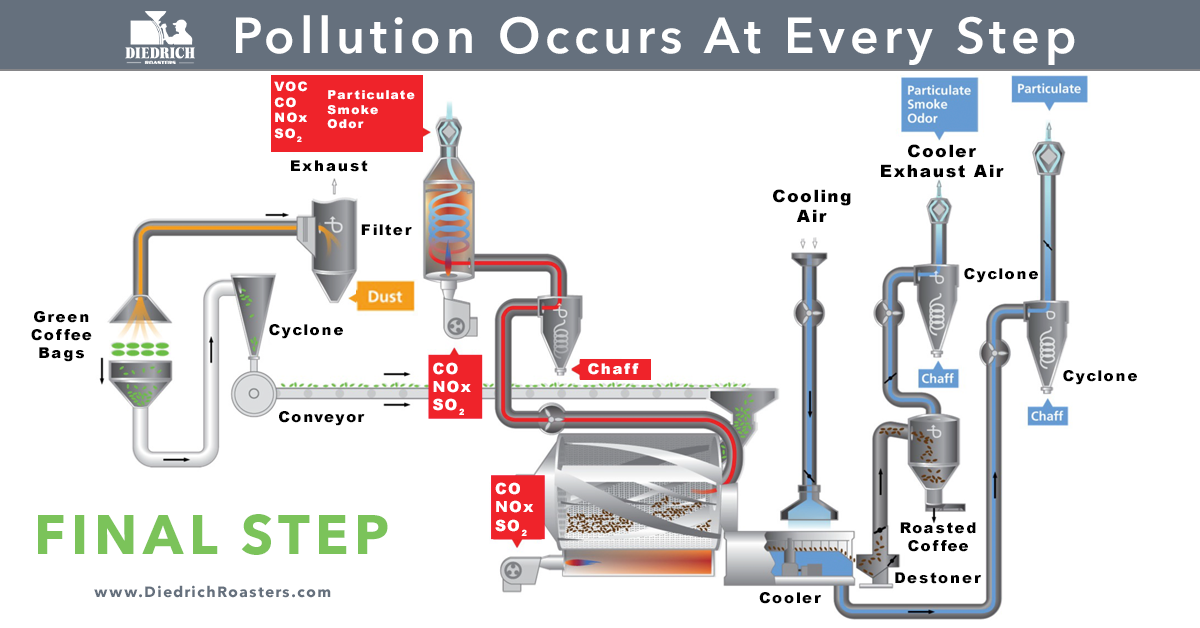

Environmental Control Systems

Environmentally friendly technologies reduce energy usage and emissions without affecting aroma or flavor.

Quality components, environmental awareness, and a commitment to stewardship are keys to caring for our environment.

This is why we design and engineer each roaster to mitigate environmental controls.

Diedrich Roasters are designed with precision to operate at a high degree of repeatability with air quality control devices in place which will meet your environmental code.

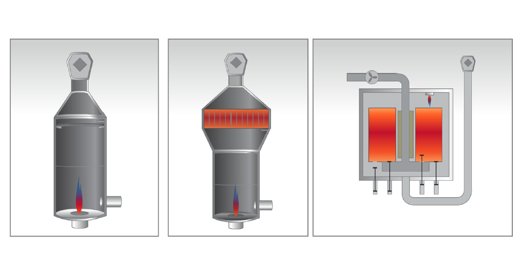

Thermal Oxidizer

Designed to destruct pollutants (VOCs, PMs, CO) from coffee roasters up to 95% efficiency at operating temperatures between 1200 and 1600º F.

Catalytic Oxidizer

Designed to destruct pollutants (VOCs, PMs, CO) from coffee roasters up to 98% efficiency between 640 and 750º F.

We Help You Determine Your Environmental Control Needs

Coffee Roasting and Air Quality Management, Emissions, and Abatement

Air quality management, emissions and abatement, and coffee roasters are all interconnected in ways that are crucial for both the environment and the coffee industry. The coffee roasting process also produces a significant amount of emissions, including carbon dioxide, nitrogen oxides, and other pollutants. These emissions can have negative impacts on the environment and on public health, which is why it is important for coffee roasters to carefully manage their emissions and implement strategies to reduce them.

Contact us for More Information

Or fill out this form and one of our friendly team members will be in contact as soon as possible.

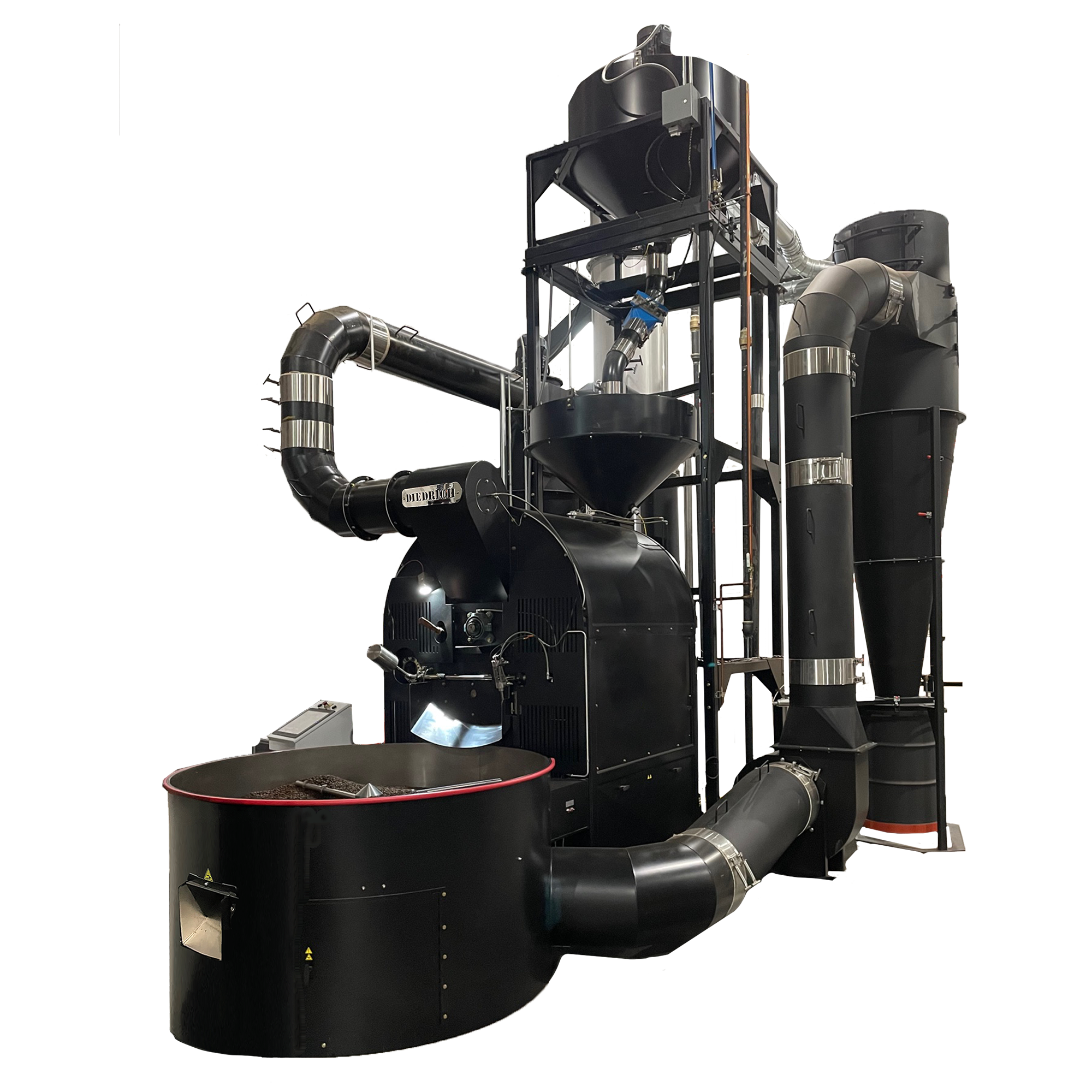

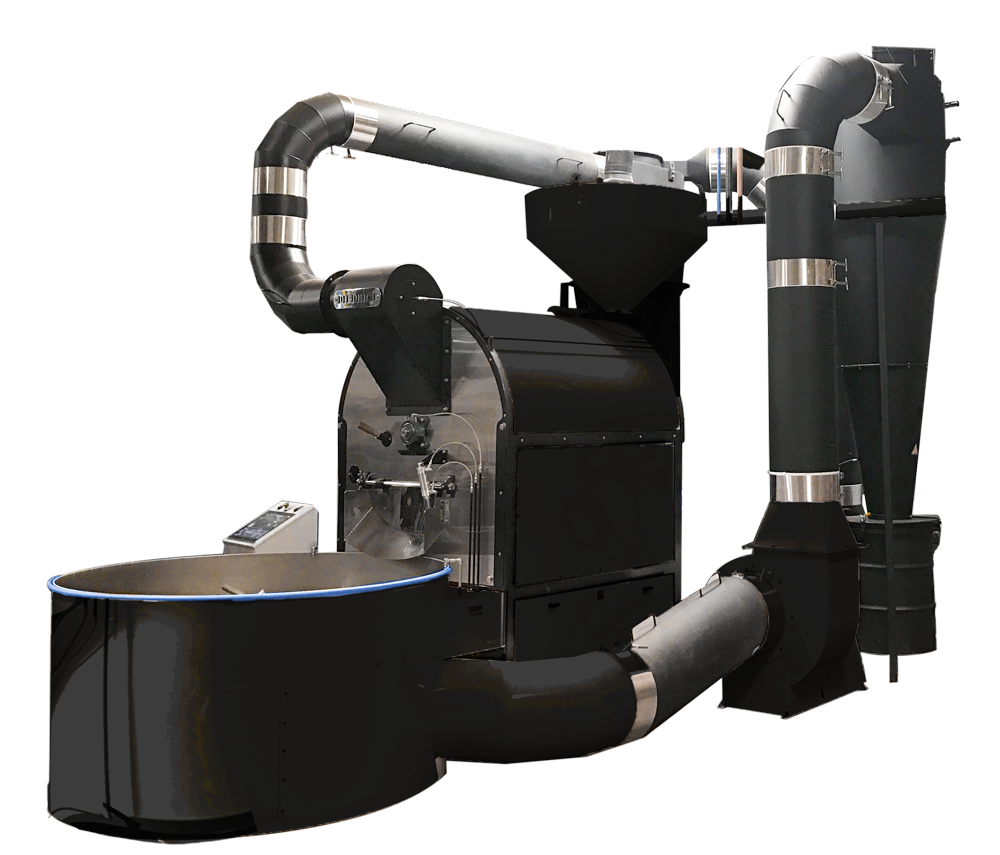

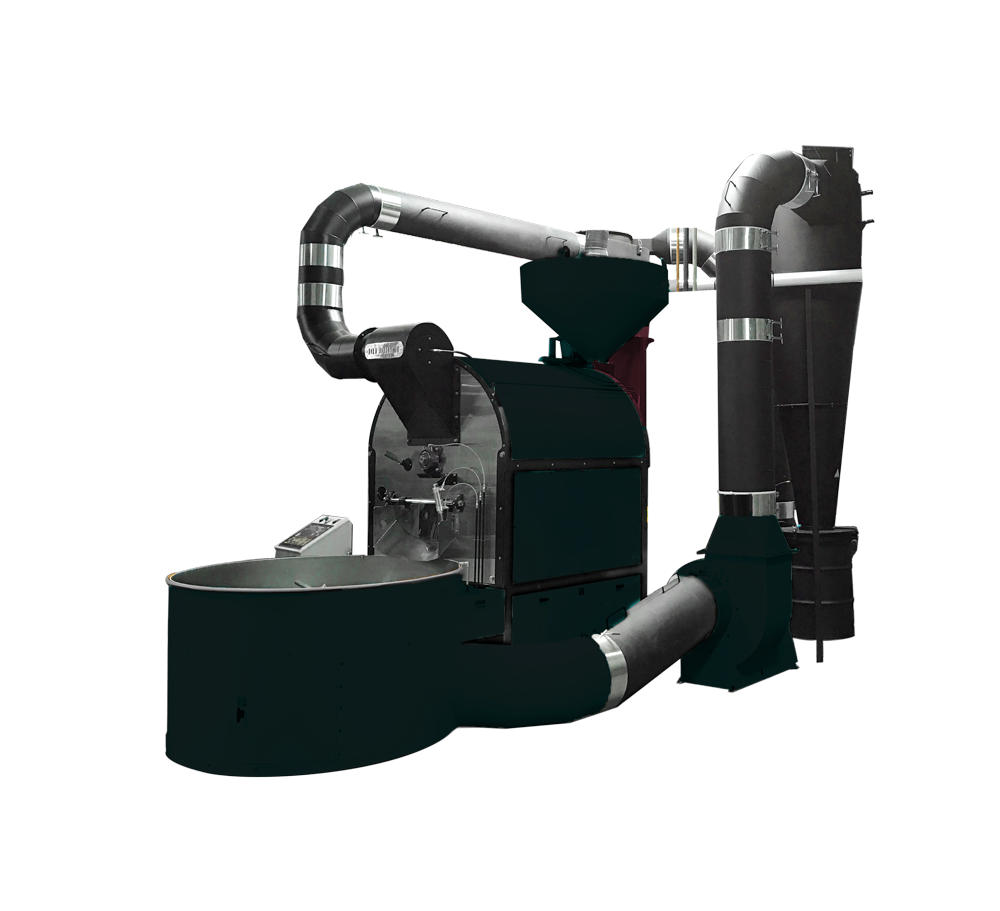

Commercial Roasters

A Quality Roast Every Time, at Any Scale.

COMMERCIAL ROASTERS

CR-280

Hourly capacity — Up to 2156 lbs

COMMERCIAL ROASTERS

CR-140

Hourly capacity — Up to 1078 lbs

Batch size for the CR-280 is approximately 616 lb (280 kg) of green coffee. In addition to full batch capacity, our roasters are also designed to roast half batches.

Batch size for the CR-140 is approximately 140 Kg/308 lbs. In addition to full batch capacity, our roasters are also designed to roast half batches.

COMMERCIAL ROASTERS

CR-70

Hourly capacity — Up to 540 lbs

COMMERCIAL ROASTERS

CR-35

Hourly capacity — Up to 270 lbs

Batch size for the CR-280 is approximately 616 lb (280 kg) of green coffee. In addition to full batch capacity, our roasters are also designed to roast half batches.

Batch size for the CR-140 is approximately 140 Kg/308 lbs. In addition to full batch capacity, our roasters are also designed to roast half batches.

Exceptional Customer Support

Experienced, Knowledgeable, Dependable

The Diedrich Difference.

Every roaster is meticulously designed and engineered to deliver quality and consistency to achieve superb results. Your roaster is built to fulfill your specific roasting requirements and specifications and to fit seamlessly into your workflow.