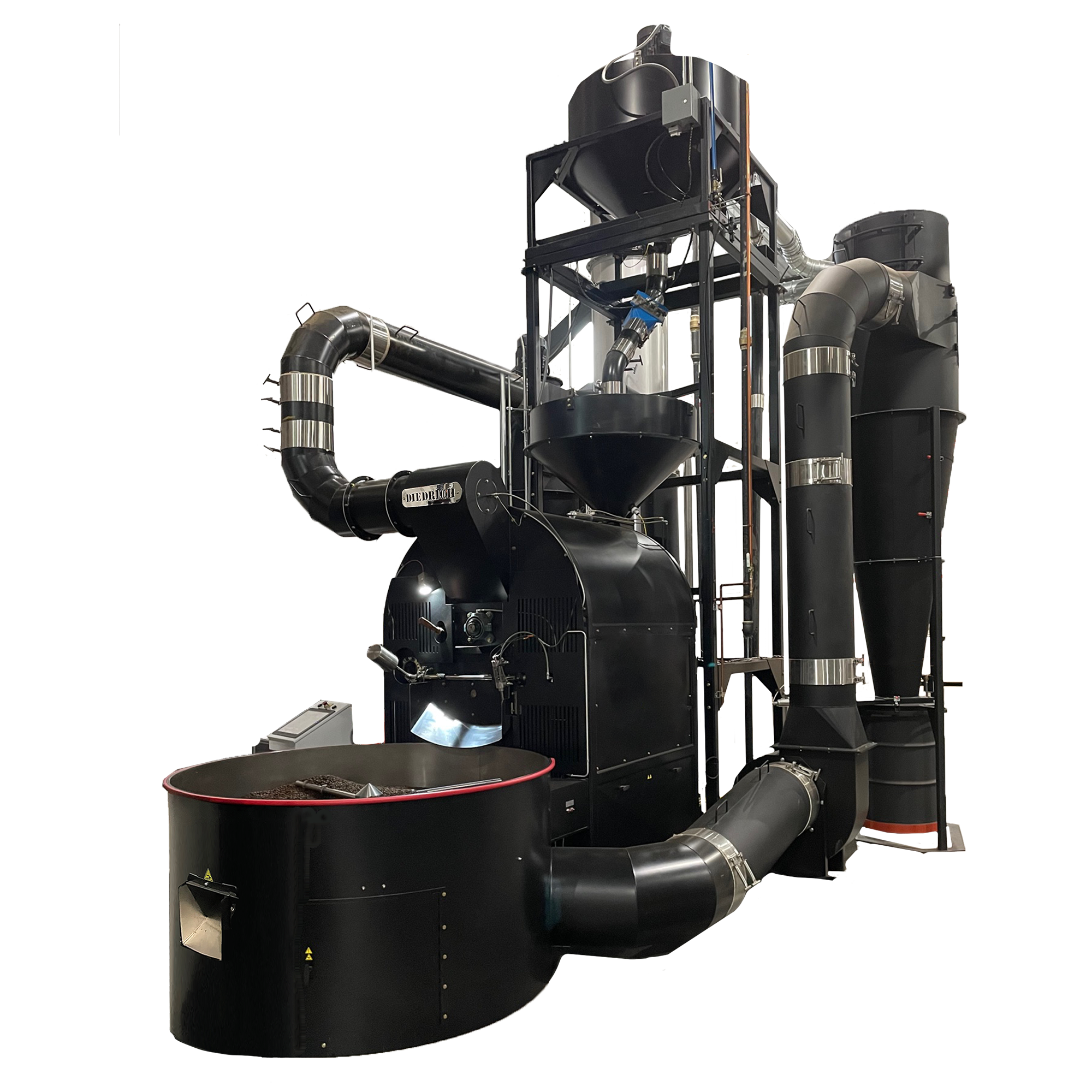

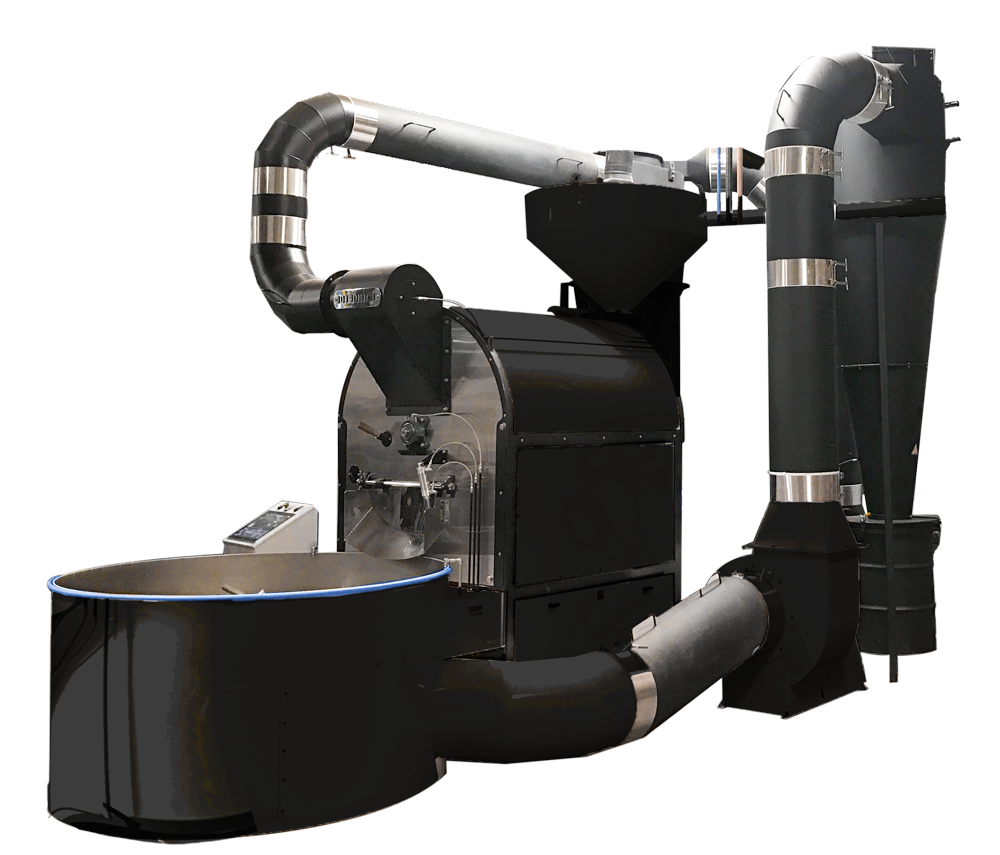

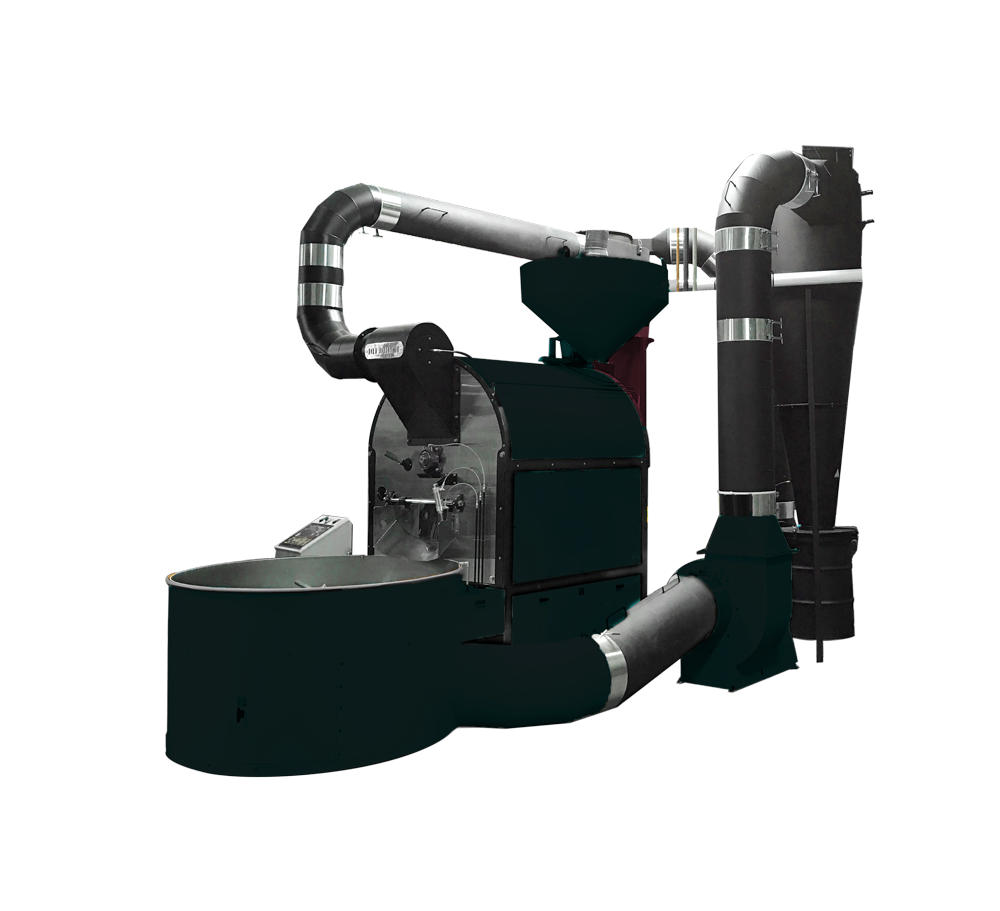

The DR-360

Approx. 6-bag roaster, featuring advanced technology and controls.

-

-

-

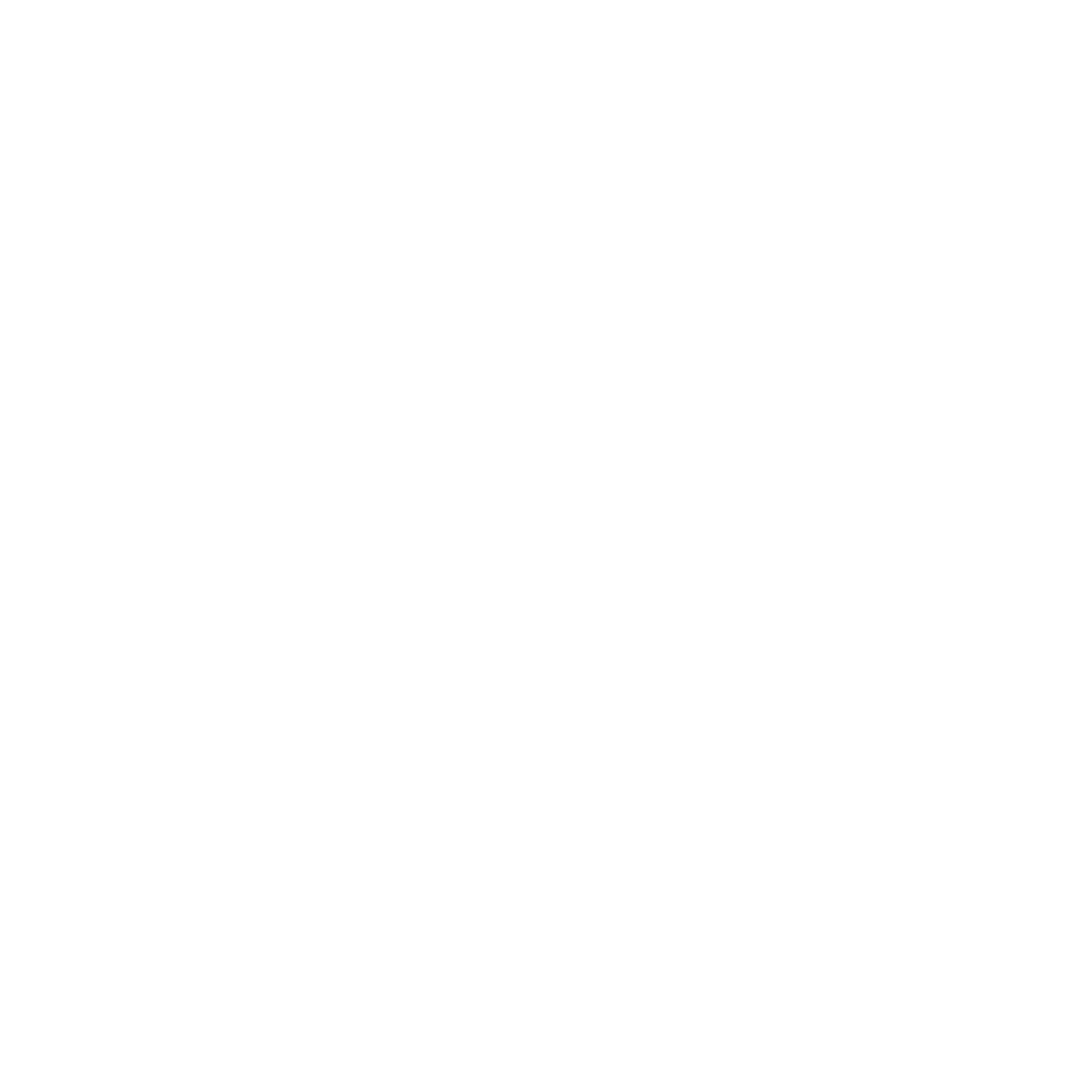

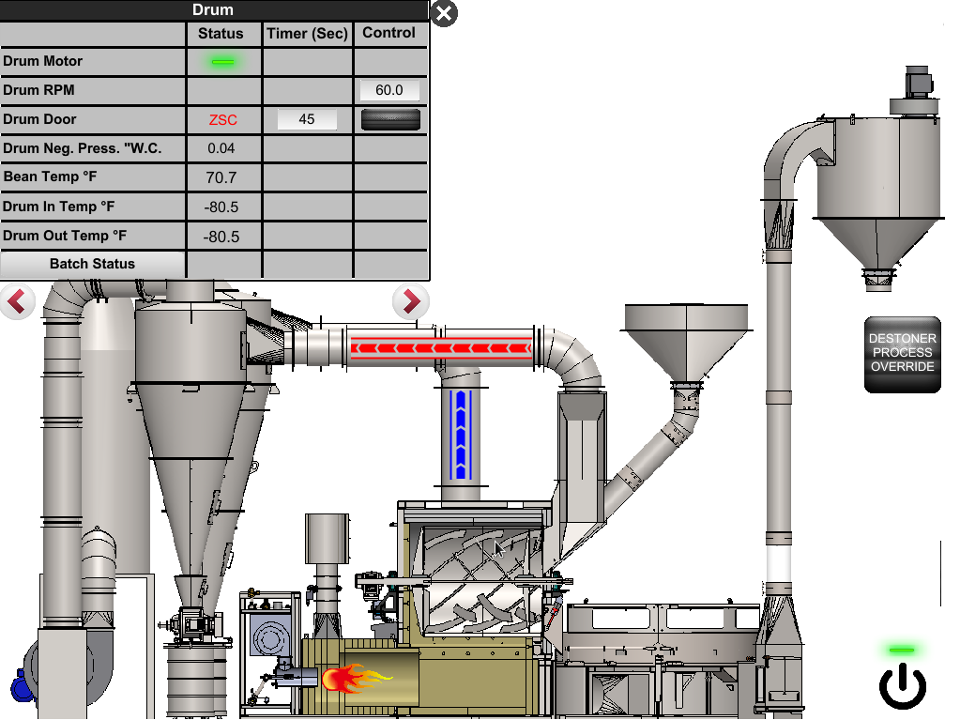

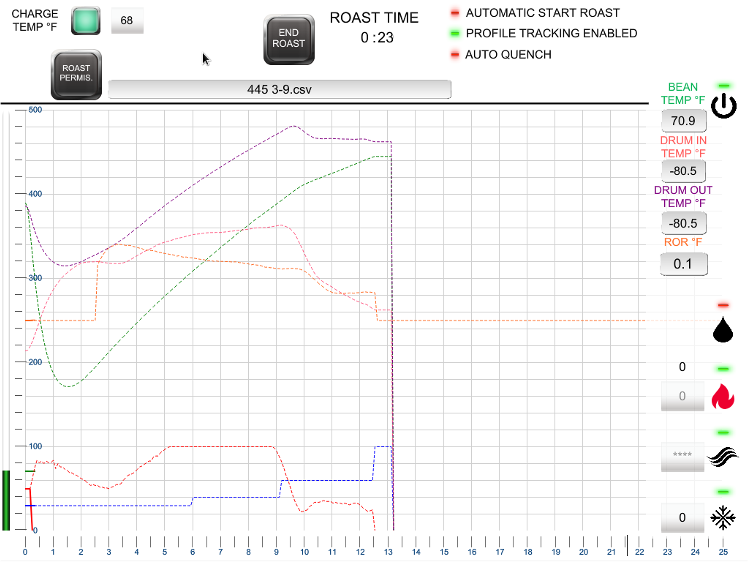

- Fully Automated Roaster Controls, designed and programmed in-house

- DR Flex Industrial

- New & Improved safeties, stable machine control, consistency in machine and product

- Rockwell Automation

-

-

What are Your Current Challenges

for Service & Support?

Diedrich Provides Solutions.

- All of our machines are completely assembled so all the components can be tested prior to shipment.

- Customers are invited on-site to witness and participate in the Factory Acceptance Test (FAT).

- New controls platform including the latest profile roasting features and safety design supported and serviced from the US.

Control design for the Roaster includes:

-

- Safeties for man and machine

- Interface capability with existing plant and process control systems

- Profile Roasting

We are at your service. Send us an email or speak directly with our Professional Sales Team.

Noteworthy Consulting

Grow Your Business with Expert Advice and Support

Equipped to help grow your business

with expert advice and exceptional support.

In addition to crafting exceptional specialty and commercial roasters, Diedrich offers world-class consulting, facilities concept design, and comprehensive educational programs in all facets of the coffee industry. With decades of experience, we are able to explore and facilitate all segments of the market by incorporating innovation and new technologies to meet today’s challenging demands.

We Partner with You to Identify Your Specific Needs, Analyze Your Workspace & Workflows, and Create Appropriate Capacity Goals

With locations in Chicago and Idaho, our US-based team is easily accessible to our customers. Our core competencies and deliverables are based on designing precise roasting systems, business strategies, and complete support for your success and profitable growth.

Our Facilities & Concept Design Services Include

BUSINESS PLANNING & MANUFACTURING STEPS

- Business plan development

- Facility evaluation

- Definition of current and future state

manufacturing analysis and strategy - Production and inventory control techniques

- Identifying and understanding your market

- Distribution Strategy

- Sales and Marketing Plans

- Quality Control System Development

- Employee Safety & OSHA concerns

PROCESS ENGINEERING SERVICES

- Process project development

- Process packaging design and engineering

- Equipment specifications and procurement

- Line layouts, process or packaging

- Electric/controls

- Equipment installation

- Startup and commissioning

SERVICES

- Equipment field support

- Café design and training

- Roaster Training

- Food Safety

- Regulatory Agency Changes

- Permitting Services

- Risk Management thru the whole chain

- Equipment decisions

Contact us for More Information

Or fill out this form and one of our friendly team members will be in contact as soon as possible.

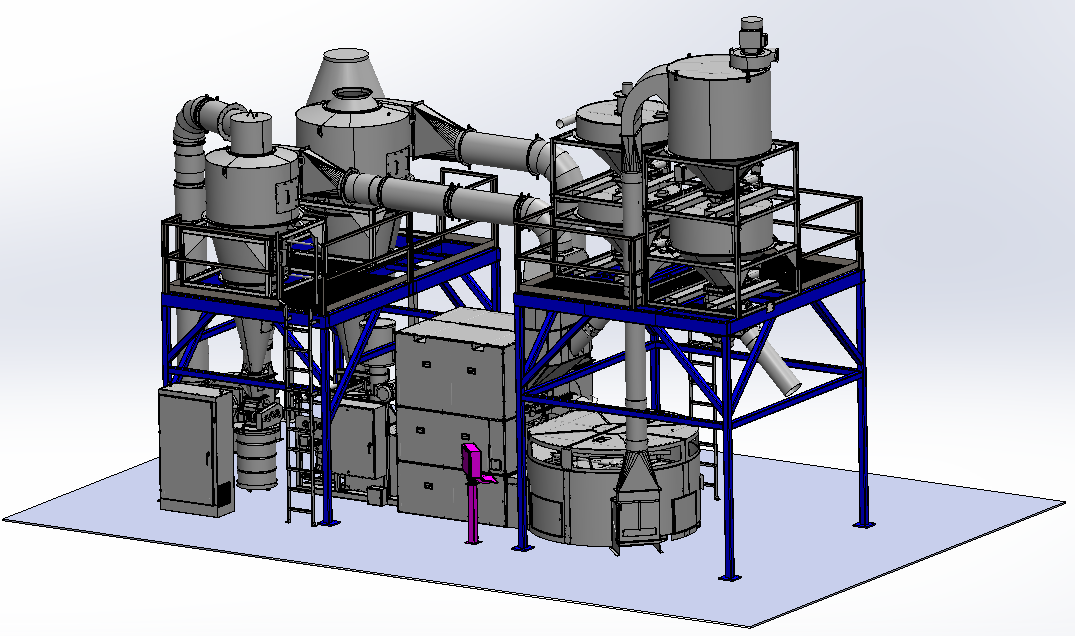

COMMERCIAL ROASTERS

CR-280

Hourly capacity — Up to 2156 lbs

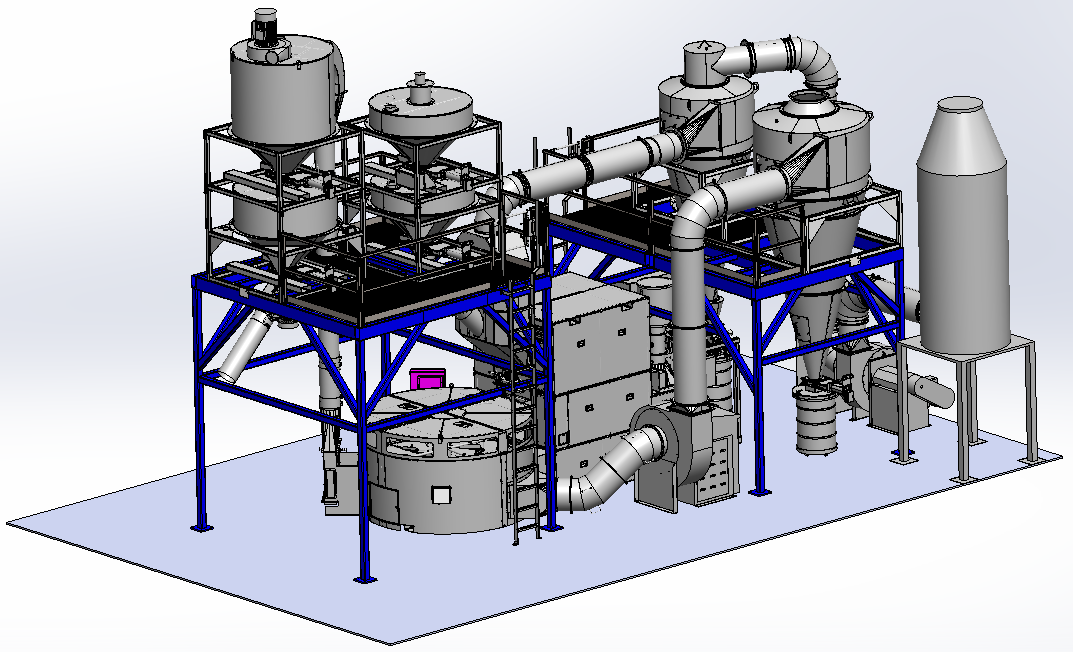

COMMERCIAL ROASTERS

CR-140

Hourly capacity — Up to 1078 lbs

Batch size for the CR-280 is approximately 616 lb (280 kg) of green coffee. In addition to full batch capacity, our roasters are also designed to roast half batches.

Batch size for the CR-140 is approximately 140 Kg/308 lbs. In addition to full batch capacity, our roasters are also designed to roast half batches.

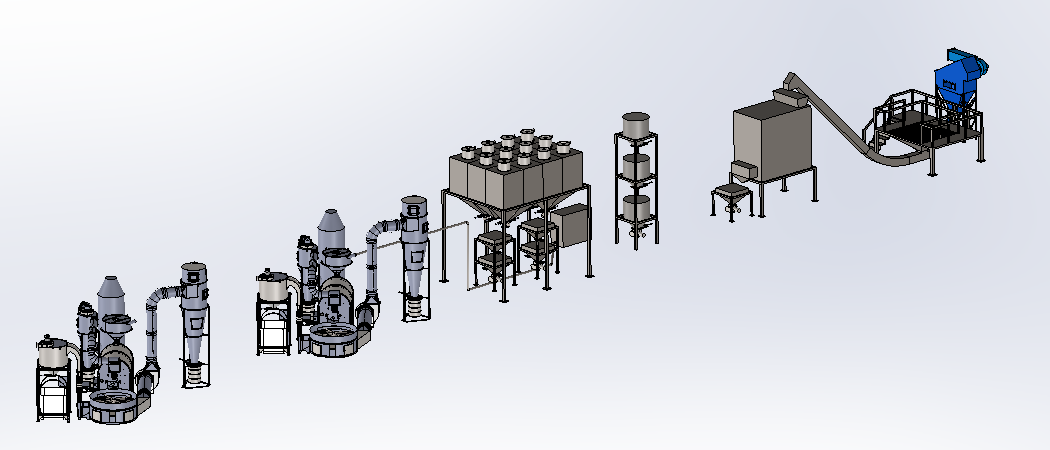

COMMERCIAL ROASTERS

CR-70

Hourly capacity — Up to 540 lbs

COMMERCIAL ROASTERS

CR-35

Hourly capacity — Up to 270 lbs

Batch size for the CR-280 is approximately 616 lb (280 kg) of green coffee. In addition to full batch capacity, our roasters are also designed to roast half batches.

Batch size for the CR-140 is approximately 140 Kg/308 lbs. In addition to full batch capacity, our roasters are also designed to roast half batches.